| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Loading

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Countertop SurfacesThe Reduction Of E. Coli

O. Peter Snyder, Jr., Ph.D. Introduction

These materials are commonly used in home kitchen countertop construction.

Today, it is understood that many food items that we purchase are highly contaminated with pathogenic microorganisms, and it is necessary for the home cook to make these foods safe. Often, the first step in food preparation is cutting and manipulating the food to get it ready. It is essential that the countertop surfaces be cleaned after raw food has touched the surface. Otherwise, there can be cross-contamination, and the people eating the food prepared on the cross-contaminated surface can become ill. This study identifies the cleanability of these six different countertop surfaces. MethodsThe material for the countertop surfaces were supplied by Porter Novelli (1120 Connecticut Avenue NW; Washington, DC 20036-3902). The countertop sources are as follows.

The procedure for doing the experiments was as follows:E. coli ATTC# 25922, a non-pathogenic E. coli, was used as the marker organism. It was grown overnight at 35°C in a static culture of broth (International Bioproducts; 14780 NE 95th Street, Redmond, W A 98052) to an inoculum of approximately 1,000,000,000 organisms per ml. An area of 81 square inches of each of the countertop surfaces was inoculated with 1 ml of this culture in M broth. The cleaning procedure was as follows:

First, the surface was washed with a dishcloth and 2 liters of detergent (Jefco Yellow Dishsoap; Unisource / Jefco Group, Inc.; 1040 North

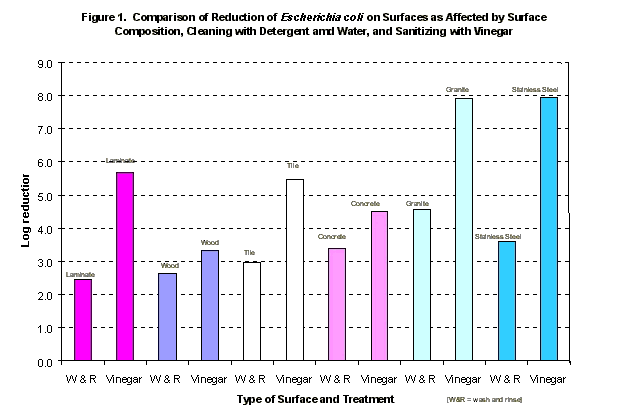

Halsted Street; Chicago, IL 60622) water in a stainless steel bowl. The surface was then rinsed, using a second bowl with 2,000 ml of clear water and a second dishcloth. The cleaning process entailed rubbing the dishcloth left to right V over the surface, rinsing it out, then, rubbing up and down and rinsing it out. The rinse step followed the wash step, using the same left-to-right and up-and-down strokes. After the countertop surfaces were washed and rinsed, they were swabbed, using a sponge swab over the entire 81 square inches of inoculated surface to find the mean reduction. The sponge swab was cultured using Violet Red Bile agar plates (International Bioproducts) and incubated overnight at 35ºC. Following the wash and rinse, the countertop surfaces were wiped with a 10% solution of white household vinegar (1 cup 5% vinegar in 9 cups tap water). The countertop surfaces were allowed to dry for 15 minutes. They were then sponge-swabbed over the 81 square inches once more, and cultured, using VRB agar to determine how many E. coli had been destroyed by the vinegar. ResultsThe results of the experiment are shown in Table 1 as logarithms of counts per 81 square inches of surface. In the column, "Real Number," the logarithms of the average are converted to real numbers. In each experiment, the first column presents the log mean count of the organisms recovered. The second column under each experiment shows the log reduction in bacteria due to the wash and rinse process or due to the vinegar application. The results are also shown in Figure 1. The retention of the E. coli was from most retained to most removed as follows:

For the laminate, washing and rinsing reduced the bacterial counts by about 285 to 1, as shown in the summary column. When the vinegar was applied, the overall reduction was increased to about 500,000 to 1. For the wood, washing and rinsing reduced the bacterial counts by about 500 to 1, as shown in the summary column. When the vinegar was applied, the overall reduction was increased to about 2,000 to 1. For the tile, washing and rinsing reduced the bacterial counts by about 900 to 1, as shown in the summary column. When the vinegar was applied, the overall reduction was increased to about 233,000 to 1. For the concrete, washing and rinsing reduced the bacterial counts by about 2,400 to 1, as shown in the summary column. When the vinegar was applied, the overall reduction was increased to about 30,600 to 1. For the stainless steel, washing and rinsing reduced the bacterial counts by about 4,000 to 1, as shown in the summary column. When the vinegar was applied, the overall reduction was increased to about 230,000,000 to 1. For the granite, washing and rinsing reduced the bacterial counts by about 36,000 to 1, as shown in the summary column. When the vinegar was applied, the overall reduction was increased to about 80,000,000 to 1. DiscussionThis experiment has shown that every countertop surface will have a different cleanability. This experiment was done with new samples. When some of these samples become worn, the reduction will probably not be as significant, except for stainless steel, which should change the least. While granite showed the greatest reduction in washing, overall, after the vinegar sanitizing, the stainless steel had the greatest reduction. ConclusionIt is very important in food safety for the designer to consider the countertop material. In this case, the stainless steel counter showed the greatest overall reduction after the wash, rinse, and sanitize processes. Table 1. Log Reduction Comparison of Non-pathogenic Escherichia coli on Countertop Surfaces [CFU / 81 sq. in.] as Affected by Surface Composition, Washing and Rinsing, and Sanitizing with Vinegar

Rdtn = reduction 0 = <100

This information is copyrighted by the Marble Institute of America. It was reproduced with permission from the Marble Institute of America.

Here's MORE Granite STUFF:

Return from Countertop Surfaces to Granite Counter Tops Info Return from Countertop Surfaces to Natural Stone Interiors Home |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Top Of Page | Home Page | What's New | Free Estimates | Site Map | Privacy Policy | Advertising | Contact Us | | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Copyright © 2005 - 2015 Natural-Stone-Interiors.com - All Rights Reserved.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||